From Standard to Non-Standard

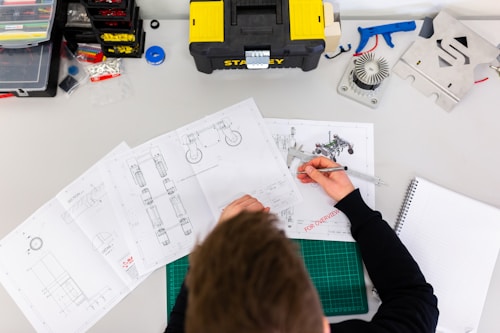

We Customize Every Product for Your Project

We support customization of multiple product categories, non-standard sizes, special structures, and OEM/ODM services, handling the entire process from design to delivery.

Contact Our Customization ConsultantWhy Choose Our Custom Solutions

From concept to delivery, we provide comprehensive customization services tailored to your specific requirements

Diverse Product Range & Non-Standard Sizes

Support for multiple product categories across our entire product line. We can customize sizes, specifications, shapes, and structures according to your exact requirements, no matter how unique.

Simplified Process & Rapid Response

Streamlined workflow from specification submission to quotation, sample confirmation, and production delivery. Our expert team responds within 24 hours with detailed feasibility analysis and accurate quotes.

Technical Capability & Quality Assurance

Advanced manufacturing capabilities including CNC machining, injection molding, 3D printing, and sheet metal fabrication. ISO certified quality control ensures every custom product meets international standards.

Flexible Order Quantities & Fast Delivery

Unlike standard products, our custom solutions offer flexible MOQ options suitable for both small batch production and large-scale manufacturing. Expedited delivery available for urgent projects.

One-Stop Service from Design to Delivery

Complete support including design consultation, technical drawing review, sample confirmation, production management, quality inspection, packaging, logistics coordination, and after-sales support.

Our Customization Process

A transparent, efficient workflow designed to bring your custom product vision to life

Requirement Submission

Submit your specifications, samples, drawings, or describe your size/structure requirements through our contact form

Technical Evaluation

Our engineering team evaluates feasibility, provides detailed quotation, and confirms dimensional specifications within 24-48 hours

Sample Confirmation

Prototype or trial production samples are manufactured for your review and approval before mass production begins

Mass Production

Full-scale manufacturing, assembly, and rigorous quality inspection according to approved specifications and standards

Delivery & Support

Professional packaging, logistics coordination, delivery tracking, and comprehensive after-sales technical support

Custom Solutions Success Stories

Real projects that showcase our customization capabilities and expertise

Custom Electronic Enclosures

Developed non-standard sized aluminum enclosures with custom mounting holes and ventilation patterns for a leading IoT device manufacturer. Modified dimensions by 30% from standard sizes to fit unique PCB layouts.

Medical Equipment Components

Customized plastic injection molded components with special antimicrobial materials and non-standard dimensions for medical device assembly. Full compliance with medical industry standards.

Industrial Automation Parts

Precision CNC machined parts with tolerances to ±0.02mm and custom surface treatments. Delivered 500+ unique part numbers with various non-standard dimensions for automated production lines.

Our Customization Capabilities

Advanced manufacturing technologies and flexible services to meet your unique requirements

📐 Customization Options

- Non-standard dimensions and sizes

- Custom structures and configurations

- Material selection and substitution

- Thickness, length, width modifications

- Color and surface finish options

- OEM/ODM branding services

🔧 Manufacturing Technologies

- Injection molding (multi-cavity molds)

- CNC machining (3/4/5-axis)

- 3D printing (rapid prototyping)

- Sheet metal fabrication

- Die casting and forging

- Surface treatment and coating

📊 Order Specifications

- Minimum Order Quantity: 100 units (negotiable)

- Small batch: 100-1,000 units

- Medium batch: 1,000-10,000 units

- Large scale: 10,000+ units

- Sample lead time: 5-10 days

- Production lead time: 15-45 days

🎨 Design Support Services

- Free technical consultation

- Engineering drawing creation from sketches

- CAD/CAM design optimization

- DFM (Design for Manufacturing) analysis

- Material and cost optimization suggestions

- Prototype development and testing

Frequently Asked Questions

Get answers to common questions about our custom manufacturing services

Ready to Start Your Custom Project?

Fill out the form below to get a free consultation and detailed quotation within 24 hours